Floor/Ceiling insulation

As heat naturally rises, it will escape almost unobstructed through the ceiling if the rooms below are heated either rarely or not at all or if they lie directly under inadequately insulated flat roofs. Particularly ceilings in older buildings are either insufficiently insulated or have no insulation at all, especially the uppermost storey and the cellar ceiling. Precious heating energy flows practically unhindered into the unheated rooms producing high energy costs. By insulating the ceilings with cellulose insulation material, the heat stays where it belongs.

Floor insulation is used exclusively as a non-pressure-resistant insulation on the horizontal level (ceiling on the top storey, between joists in a wood-joist floor construction).

If the wood-joist floor construction is suitably accessible, the insulation product made of cellulose fibers is processed by machine and blown on as an open layer into the cavities. THERMOFLOC floor filling is particularly recommended for this insulation method.

If the wood-joist floor construction is not accessible, the cellulose insulation material is transported into the hollow spaces by means of specially equipped blowing machines. THERMOFLOC blow-in insulation has proved to be a very suitable product for this purpose.

Apart from being the ideal thermal insulation product, cellulose fibers, due to their nature, have also perfect sound absorbing and regulating properties, providing adequate protection from noise disturbance to ensure peace and tranquility as well as health benefits. Depending on the application, our cellulose insulation material makes sure that unpleasant noise does not penetrate from outside, sound transmission between rooms is reduced and reverberation in the rooms are kept to a minimum. Both in terms of airborne sound caused by loud music, for example, or impact sound.

Examples of use

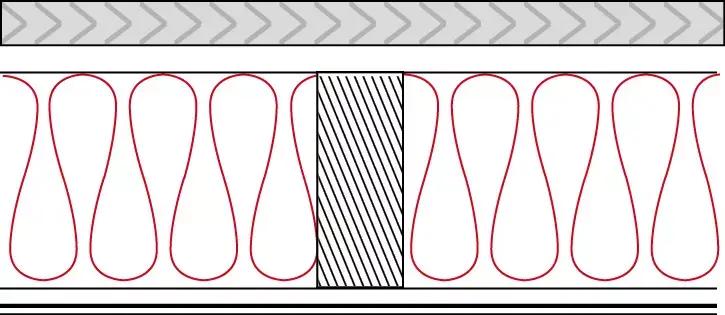

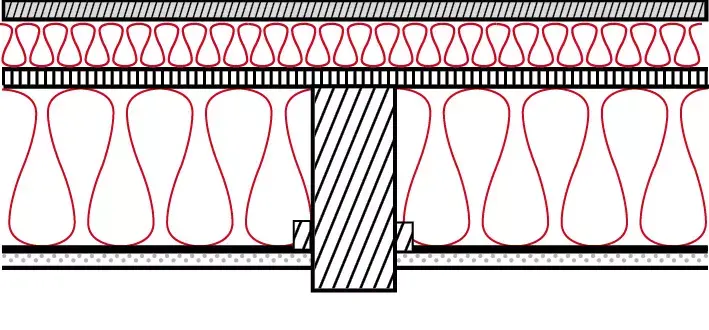

Braced Ceiling, uppermost storey ceiling, possible to walk on top

| Construction | Thickness |

|---|---|

| 1. Spruce wood cladding | 35 mm |

| 2. Soft fibreboard | 19 or 24 mm |

| 3. Tie beams/THERMOFLOC Fibre * | 140-300 mm * |

| 4. THERMOFLOC Vapour barrier | |

| 5. Evenly spaced slats | 23 mm |

| 6. Gypsum wallboards | 15 mm |

* THERMOFLOC insulation thickness in mm = calculated U-value (W/m²K)

140 = 0.22 | 160 = 0.2 | 180 = 0.18 | 200 = 0.16 | 220 = 0.15 | 240 = 0.14 | 260 = 0.13 | 280 = 0.12 | 300 = 0.11 |

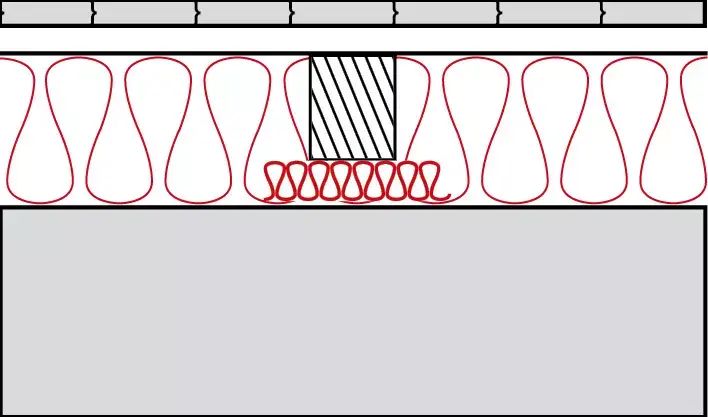

Storey Ceiling with subfloor on cushioning wood between living rooms

| Construction | Thickness |

|---|---|

| 1. Strip flooring | 22 mm |

| 2. Subfloor | 24 mm |

| 3. Construction timber/THERMOFLOC Fibre * | 50-160 mm * |

| 4. Solid ceiling | 180 mm |

* THERMOFLOC insulation thickness in mm = calculated U-value (W/m²K)

50 = 0.48 | 60 = 0.43 | 70 = 0.38 | 80 = 0.35 | 90 = 0.32 | 100 = 0.29 | 120 = 0.25 | 140 = 0.22 | 160 = 0.2 |

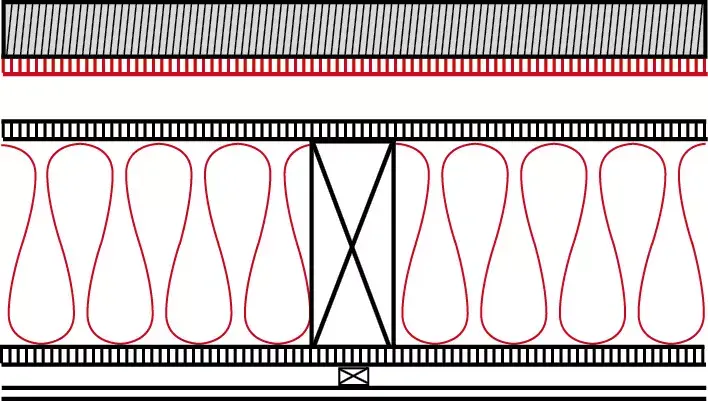

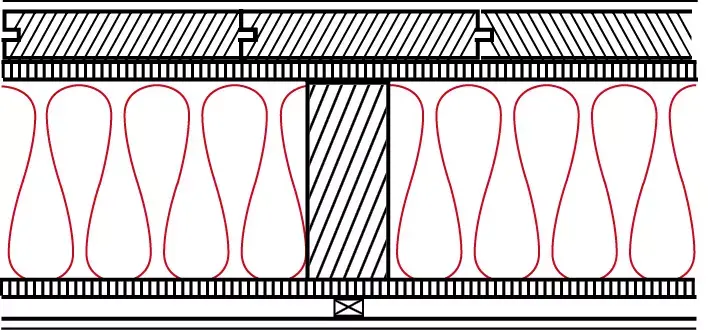

Storey Ceiling, for apartment partition ceilings, timber floor

| Construction | Thickness |

|---|---|

| 1. Timber floor | 21 mm |

| 2. Wood fibre insulation board | 40 mm |

| 3. Concrete paving stone | 50 mm |

| 4. OSB/Plywood | 22 mm |

| 5. Beams/THERMOFLOC Fibre, cavity filling * | 160-220 mm * |

| 6. Spring rail | 30 mm |

| 7. Gypsum wallboards | 12,5 mm |

* THERMOFLOC insulation thickness in mm = calculated U-value (W/m²K)

60 = 0.32 | 80 = 0.27 | 100 = 0.24 | 120 = 0.21 | 140 = 0.19 | 160 = 0.17 | 180 = 0.16 | 200 = 0.15 | 220 = 0.13 |

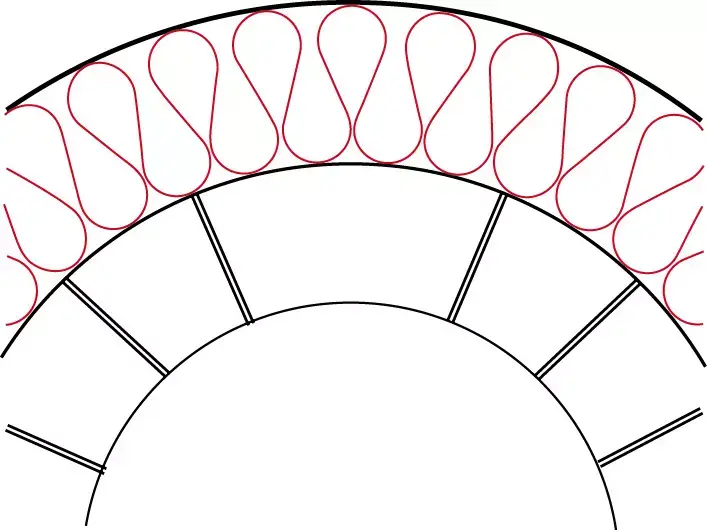

Vaulted Ceiling

| Construction | Thickness |

|---|---|

| 1. THERMOFLOC fibre * | 140-300 mm * |

| 2. Natural stone | 250 mm |

* THERMOFLOC insulation thickness in mm = calculated U-value (W/m²K)

140 = 0.23 | 160 = 0.2 | 180 = 0.18 | 200 = 0.17 | 220 = 0.15 | 240 = 0.14 | 260 = 0.13 | 280 = 0.12 | 300 = 0.12 |

Storey Ceiling, wooden beam ceiling with concrete screed

| Construction | Thickness |

|---|---|

| 1. Screed | 50 mm |

| 2. Impact sound insulation board | 20 mm |

| 3. THERMOFLOC Pellets | 30-100 mm |

| 4. OSB/Plywood | 22 mm |

| 5. Beams/THERMOFLOC Fibre | 220 mm |

| 6. OSB/Plywood | 22 mm |

| 7. Lathing | 30 mm |

| 8. Gypsum wallboard | 12,5 mm |

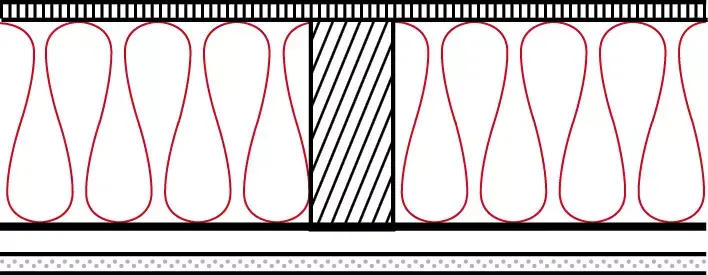

Storey Ceiling, floating timber floor

| Construction | Thickness |

|---|---|

| 1. Timber floor board | 20 mm |

| 2. THERMOFLOC Pellets | 30-100 mm |

| 3. OSB/Plywood | 30 mm |

| 4. Beams/THERMOFLOC Fibre | 160 mm |

| 5. Panelling | 25 mm |

Storey Ceiling, wooden beam ceiling with dry screed

| Construction | Thickness |

|---|---|

| 1. Timber floor board | 20 mm |

| 2. Soft fibre N-F | 40 mm |

| 3. Soft fibre cover panel | 8 mm |

| 4. OSB/Plywood | 19 mm |

| 5. Beams/THERMOFLOC Fibre * | 180-340 mm * |

| 6. OSB/Plywood | 19 mm |

| 7. Lathing | 30 mm |

| 8. Gypsum wallboard | 15 mm |

* THERMOFLOC insulation thickness in mm = calculated U-value (W/m²K)

180 = 0.23 | 200 = 0.22 | 220 = 0.2 | 240 = 0.19 | 260 = 0.18 | 280 = 0.17 | 300 = 0.16 | 320 = 0.16 | 340 = 0.18 |

Storey Ceiling with wooden beam ceiling

| Construction | Thickness |

|---|---|

| 1. OSB/Plywood | 19 mm |

| 2. Beams/THERMOFLOC Fibre * | 140-300 mm * |

| 3. Waterproof layer | 0,1 mm |

| 4. Lathing | 30 mm |

| 5. Gypsum wallboard | 15 mm |

* THERMOFLOC insulation thickness in mm = calculated U-value (W/m²K)

140 = 0.38 | 160 = 0.35 | 180 = 0.31 | 200 = 0.29 | 220 = 0.27 | 240 = 0.25 | 260 = 0.23 | 280 = 0.22 | 300 = 1 |

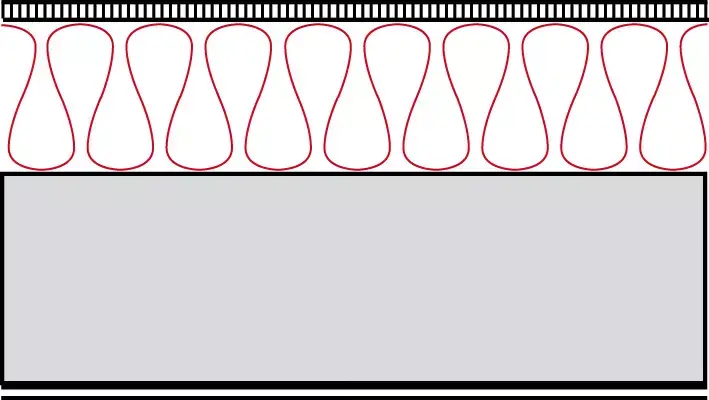

Storey Ceiling with solid cellar ceiling

| Construction | Thickness |

|---|---|

| 1. Timber floor board | 20 mm |

| 2. Lathing/THERMOFLOC Pellets * | 60-120 mm * |

| 3. Reinforced concrete ceiling | 160 mm |

| 4. Ceiling plaster | 10 mm |

* THERMOFLOC insulation thickness in mm = calculated U-value (W/m²K)

60 = 0.7 | 80 = 0.58 | 100 = 0.5 | 120 = 0.44 | 140 = 0.39 | 160 = 0.35 | 180 = 0.32 | 200 = 0.29 | 220 = 0.27 |

Isolatie van het plafond van de bovenste etage

Mocht de dakruimte van een gebouw niet tot een woonruimte kunnen worden uitgebouwd, maar aan verwarmde ruimtes grenzen, dan schrijft de energiebespaarverordening (EnEV) de isolatie van het plafond van de bovenste etage voor. Mocht de dakruimte niet gebruikt worden, dan kan de isolatie van het plafond van de bovenste etage zeer eenvoudig achterwege blijven, omdat zij niet met een dragende deklaag wordt voorzien. Dat is zonder twijfel gunstig qua kosten, maar dit soort dakruimtes zijn niet begaanbaar en dientengevolge ook niet als bergruimte te gebruiken. Bij de constructie moet er alleen op gelet worden, dat er een loopplank ingebouwd wordt, opdat de heer des huizes of de schoorsteenveger indien nodig tot aan het dakuitgangsluik kan komen. Mocht het plafond van de bovenste etage met een cellulose-isolatie worden voorzien, dan moet er bij zwaar geventileerde daken op gelet worden, dat de bovenste laag van de isolatie met water besproeid en verhard wordt.

Further areas of application

THERMOFLOC quality certificates